Fleet readiness with AM

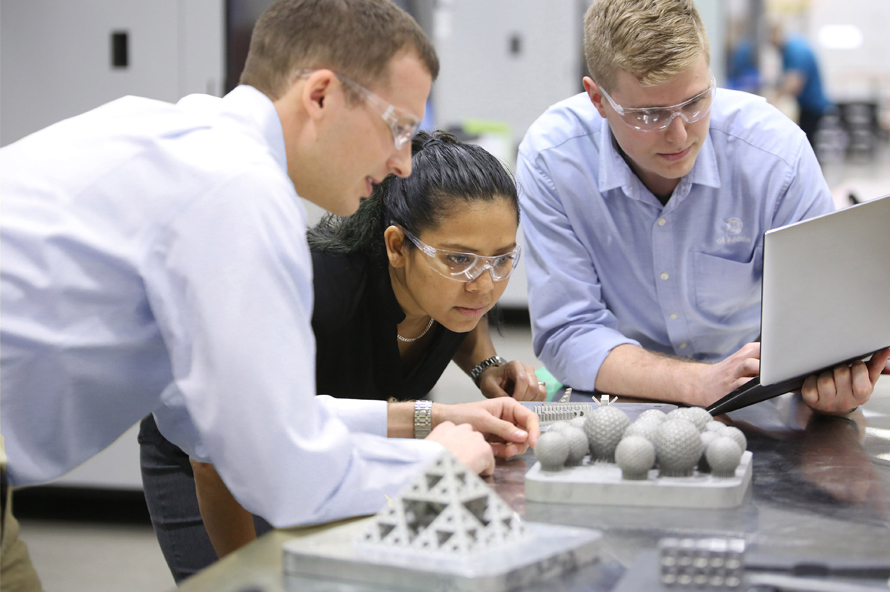

An uncertain world with a complex threat matrix requires advanced platforms with modern supply chains. Whether on the ground, in the air, at sea, or in space, additive manufacturing is the game-changing technology needed for more capable military products, providing benefits like organic support and a better fleet.

Repair and restoration

Precise repair and restoration are critical in the maintenance repair and overhaul (MRO) industry as it ensures end-of-life products are returned to as-new condition. Traditional repair processes are manual and time-consuming.

Advantages of AM:

• Increases efficiency while maintaining quality

• Saves time and costs

• Enables on-demand production

Supply Chain

Additive can help optimize manufacturing processes and streamline the larger supply chain. You can shorten lead times and reduce costs by additively manufacturing hard-to-find and low-volume parts on-demand.

Advantages of AM:

• Reduces lead time and simplifies supply chain

• Enables mass customization

• Extends product life span