Interview with AP&C’s first and longest-serving employee

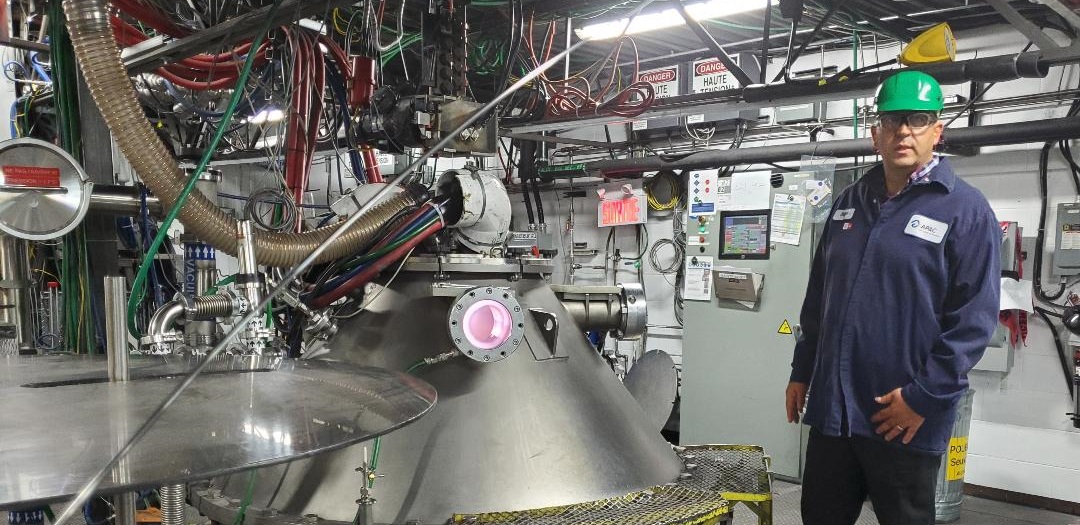

Without high-quality powders, delivering the potential that metal additive technology promises would not be possible. GE Additive’s powder business, AP&C based in Montreal, Canada, produces powders that are used in metal additive manufacturing process.

The company transforms titanium, nickel and aluminum into metal powders ready for use in a wide range of additive manufacturing applications spanning highly regulated industries such as aerospace and medical to most industrial sectors.

An integral part of metal additive’s momentum is a legion of specialists, materials scientists, metallurgists and engineers from a range of disciplines pushing the boundaries of powder technology day in, day out.

That includes around 200 employees at AP&C’s two sites just outside Montreal, in Canada’s Quebec Province.

We sat down with AP&C’s first full-time employee, Hafet Senoune, a production supervisor, who was hired in 2003 to a newly formed technology company with big ideas and big ambitions.

Scaling from Innovative Start-Up to World Leader

“Back then we were a young start-up company that specialized in the production of metal powders and thermal coatings made by plasma and wanted to become a player in the field of advanced materials,” says Hafet.

Over the years, the company patented and acquired a range of technologies in this field and built a technical team to drive innovation. Efforts soon focused on the development of its proprietary advanced plasma atomization (APATM) technology to produce superior titanium powders. Hafet joined the AP&C team at its inception as a process and laboratory technician.

“It continues to be an exciting adventure! I was involved from the very beginning, charged with improving the plasma atomization technology and making it robust and efficient. Over the years we’ve gone from having one single reactor to now more than 15 today. In that time, we’ve increased production capacity by a factor of more than 50.”

In 2014 AP&C was acquired by Arcam and then both were later acquired by GE in late 2016 as part of the formation of GE Additive. This was a defining moment in AP&C's development and has helped accelerate it l become the world's largest producer of spherical titanium powder.

In his current role as a production supervisor, Hafet is responsible for the atomization team, training and supervision of new employees and knowledge transfer.

The biggest change has been the ability to scale both research and development and production. On the culture side, joining a company with the international breadth of GE, he appreciates the company’s high value of inclusion and diversity and the opportunity to work with customers and teams around the world.

In addition to changes at the company, the powder industry itself has undergone massive transformation. According to Hafet, the powder industry continued to evolve at a dizzying pace, especially as more companies embrace metal additive manufacturing, which in turn has propelled powder development and what was thought possible.

“It has been astonishing and a privilege to see firsthand the great speed of evolution and the expansion in the aerospace and medical sectors. In those sectors alone, our customers around the world range from the largest additive super-users to nimble start-ups, and we get to collaborate closely with all of them to ensure they are successfully using our powders. This is just the beginning and through that dialogue we learn a lot from each other,” he added.

According to Hafet, the next steps for additive manufacturing are increasing the production rate, improving operational excellence and diversifying products.

Culture, Change and Transformation

With 17 years now under his belt at AP&C, Hafet has seen a lot of transformation and change.

Hafet has a high value for commitment and determination, and notes that when you are committed to something, you often succeed.

This extends across both his personal and professional career. Born in Algeria, Hafet came to Quebec, Canada, because of the opportunity to live and work in an area with great depth of knowledge and the opportunity to grow technically, in addition to being part of a vibrant economy.

He pointed out that the cold winters of Canada are a change from the climate of Algeria, but the warmth of Quebecers makes up for it.

And while Hafet has many years ahead of him, one thing he’d like to pass along to the next generation is a sense of belonging to one another - the importance of having a community mindset.

“The choices we make, the things we do are not just for our personal good, but I believe that something that brings good to all and the commitment to this belongs to all of us. I believe this for my personal life and for my profession. I believe that additive manufacturing will change the world for the better, and I am proud to have spent most of my professional career furthering this core technology.”