Ready to make the leap to production?

GE Additive's AddWorks™ team consists of 70+ global engineers with vast experience in metal additive. They are focused on design, materials and process industrialization. For customers who are already dedicated to implementing metal additive manufacturing but are experiencing industrialization challenges, our team can help you overcome the obstacles and get to production faster.

COLLABORATE WITH US

We're building a world that works.

Every day, our talented AddWorks consulting team uses its extensive AM experience to guide customers along their additive journey. From essential trainings to final part production, the AddWorks team works shoulder-to-shoulder with our customers, helping them use this transformative technology to change their businesses—and the future.

OUR CUSTOMERS REPORT:

- Informed decision making shortens their capital equipment purchase cycle down to seven months.

- We showed the customer how to unlock enough applications to maintain full annual capacity on two machines, on their own, in four months.

- High equipment utilization rates reduce payback period and increase overall ROI.

- We taught the customer how to make critical business decisions around additive independently and cost-effectively.

Collaborate with AddWorks today to find your faster path to full-scale metal additive production.

Collaborate with us to:

Accelerate innovation

Harnessing the unique benefits of additive manufacturing, including design freedoms and the ability to iterate quickly, can help you get to market faster and lead to a competitive advantage in your industry.

Reduce risk

We can help make an additive manufacturing business case, illustrating the economic and performance benefits for your organization. We can help co-design parts, introduce disruptive design and print proof-of-concept prototypes and low-rate production. Tap into our advanced technical capabilities to qualify your metal additive parts faster and increase your success rate with additive parts.

lower costs

Whether you’re looking to additively manufacture parts in industries like aerospace, medical, automotive or any other industry, GE's AddWorks team applies best practices and a proven methodology to solve your biggest technical and business challenges. Shorten your time to market and find cost savings wherever you are in the additive process with tailored solutions designed for your team.

Improve part performance and processes

Leverage our team of additive designers, engineers and material scientists to optimize your parts and processes with a systematic approach that goes beyond the part. We will help explore product solutions that aim to differentiate your parts technically and provide significant performance benefits.

OUR SERVICES

Engineering Services

Let our experts tackle the challenges for you. We can take your part requirements and develop the application-specific design, material or manufacturing process to meet your needs so you can explore additive without adding infrastructure to adopt the technology.

With your input, our AddWorks team can:

- Characterize and qualify a material

- Design your application for metal additive

- Validate the application design

- Establish and qualify the manufacturing process for your application

After achieving low-rate initial production, we will transfer the production-ready application to you or to your additive manufacturing facility of choice.

For aerospace customers, we can qualify and run low-rate initial production in our AS9100-certified facility in the United States.

OUR SERVICES

Consulting services

Leverage our experts to work beside your team, teaching additive skills and strategies to overcome challenges in additive design, materials, manufacturing and overall production.

For instance, you may need assistance as you develop your material or process specification.

Or, you may have reached a roadblock in qualifying your hardware for production. AddWorks engineers will be there to help.

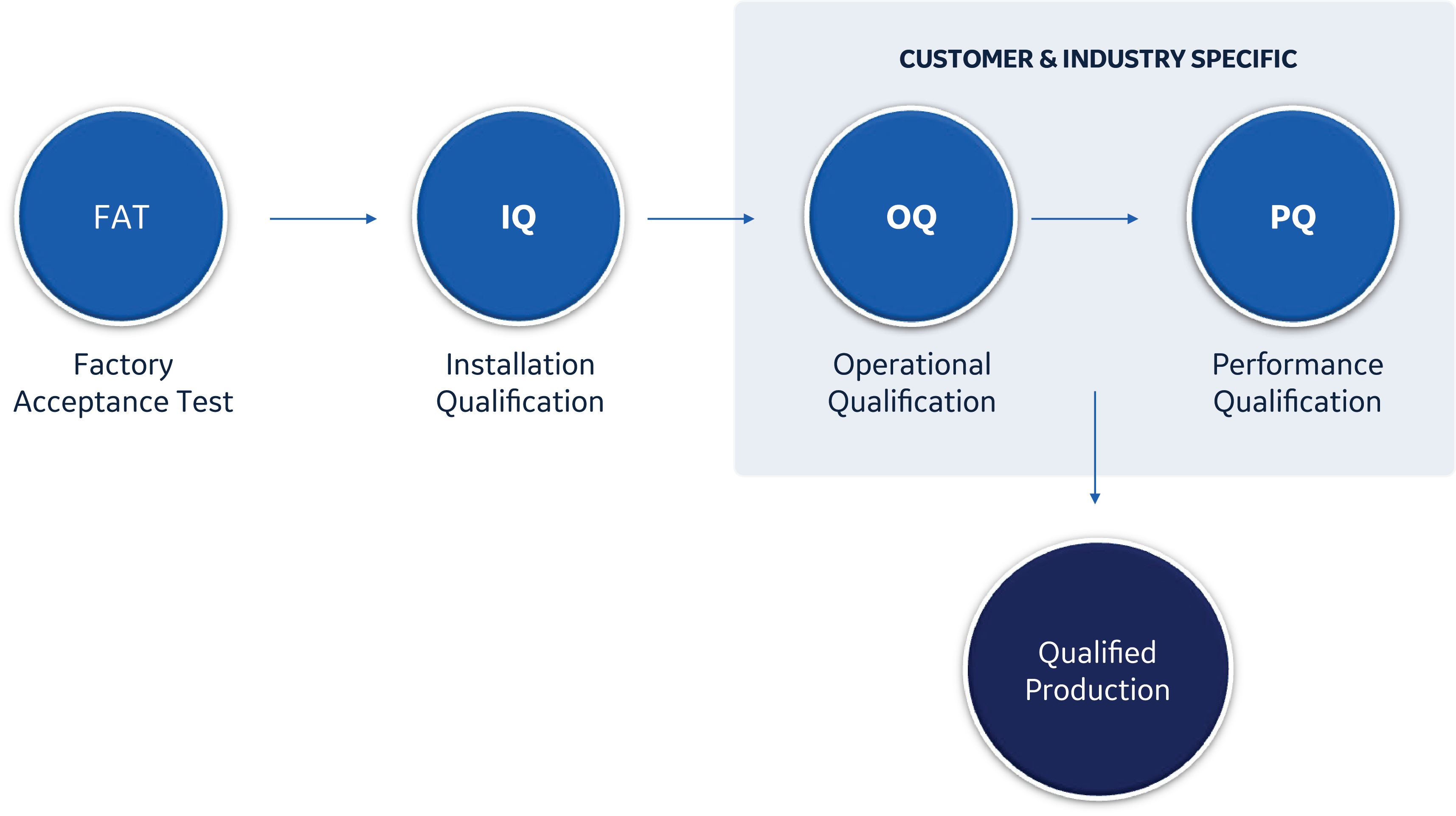

QUALIFICATION IN REGULATED MARKETS

Achieving qualification

Scaling additive production requires qualification. In regulated industries, such as orthopedics and aerospace, rigor is even more important. Our additive experts have experience qualifying hardware in highly regulated markets and can help you reduce the learning curve so you can get your product to market faster. In the end, you will qualify the machine, the material, and the process. We follow industry-wide processes to establish robust and repeatable production outcomes.

Installation Qualification (IQ)

The purpose of the IQ protocol is to provide documented evidence that the machine is installed according to documented and pre-approved specifications.

Operational Qualification (OQ)

The purpose of OQ is to demonstrate that a system operates according to written pre-approved specifications throughout a specified operating range.

Performance Qualification (PQ)

The purpose of PQ is to demonstrate that the additive process, under anticipated manufacturing conditions, consistently produces product(s) that meet all engineering requirements.

ADDITIONAL TRAINING AVAILABLE

Training

Training packages are available to customers who are engaging with our AddWorks team to achieve additive production.

Discovery Workshop

Learn how to select the right parts for AM. Create your business case by drafting a strategic roadmap that includes your project list with cost analysis, benefits and an implementation strategy.

Design Workshop

Learn to design, analyze and prepare AM parts, including support structures and process modeling. Gain a new understanding of advanced AM design and how to optimize parts for the AM process.

Industrialization Workshop

Access tools, such as machines and facilities, to enable full production. Create a step-by-step planto move toward production of your metal additive part.

Additional training packages are available.