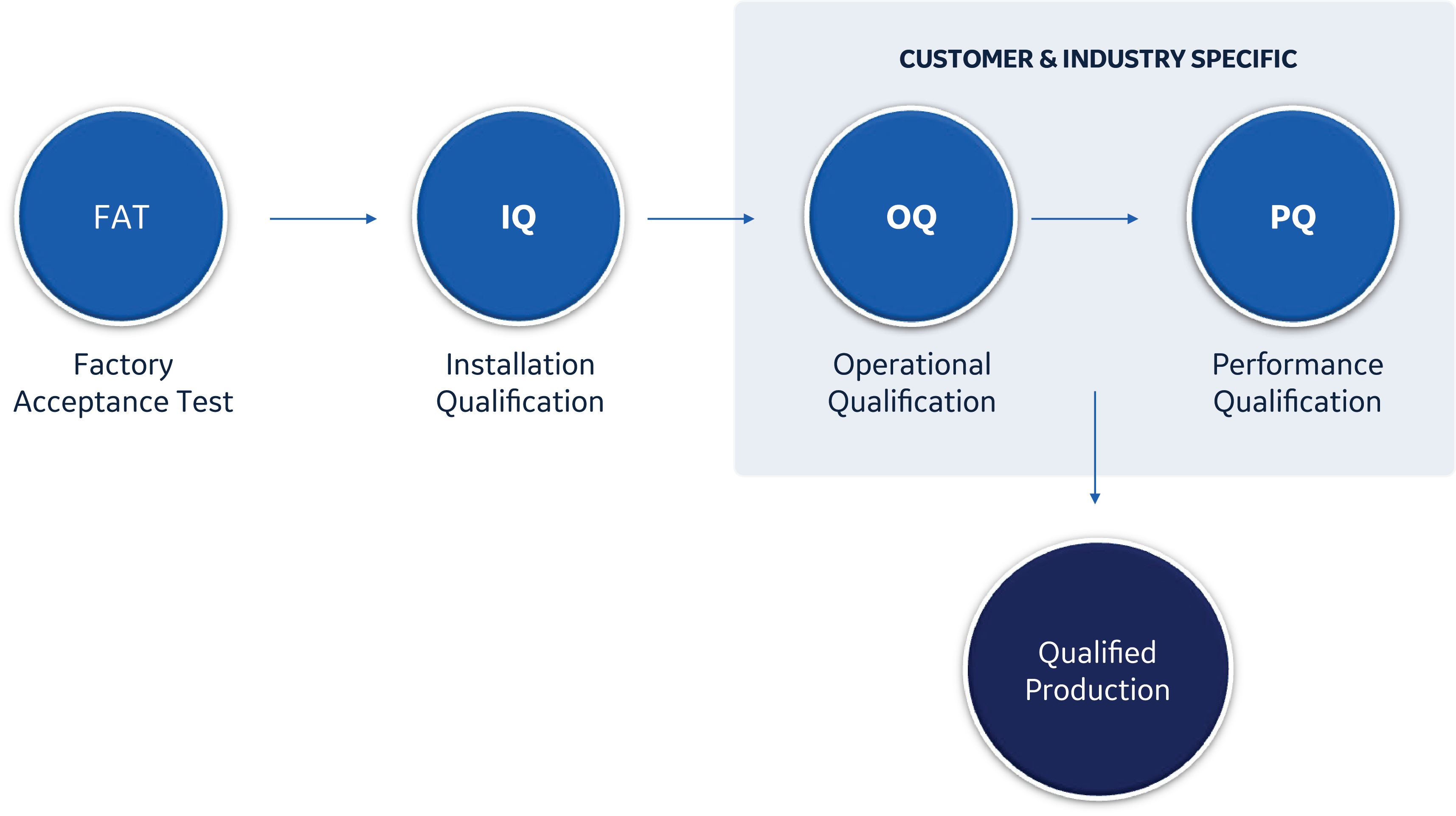

Achieving qualification

Qualification is an important aspect to scaling additive production. And more rigor comes into play when you are producing parts for regulated industries, such as orthopedics and aerospace. Our additive experts have experience qualifying hardware in highly regulated markets and can help shrink the learning curve to get your product to market faster. You will ultimately qualify the machine, the material and the process. Our approach conforms to industry-wide processes for establishing robust and repeatable production outcomes.

Installation Qualification (IQ)

The purpose of the IQ protocol is to provide documented evidence that the machine is installed according to documented and pre-approved specifications.

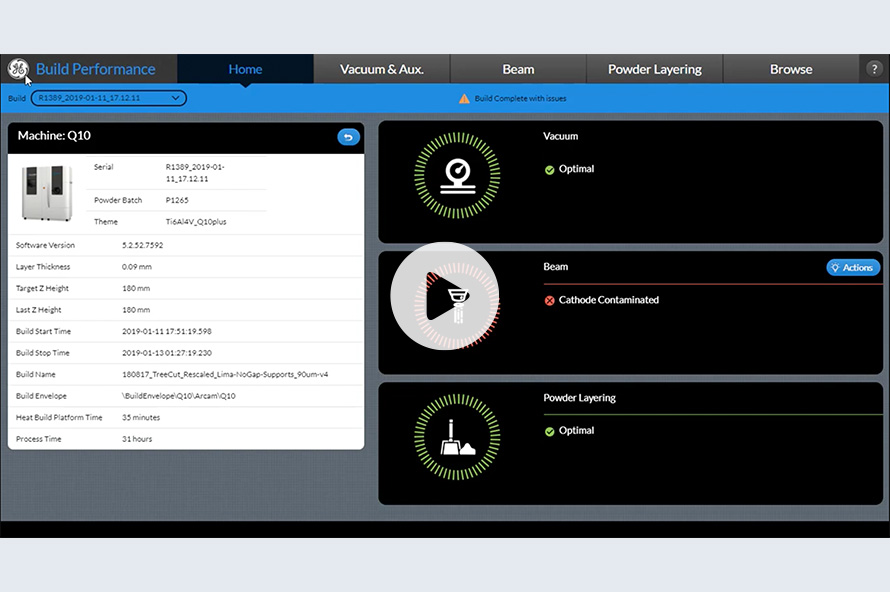

Operational Qualification (OQ)

The purpose of OQ is to demonstrate that a system operates according to written pre-approved specifications throughout a specified operating range.

Performance Qualification (PQ)

The purpose of PQ is to demonstrate that the additive process, under anticipated manufacturing conditions, consistently produces product(s) that meet all engineering requirements.