PRESS RELEASES

GE ADDITIVE

Collaborate alongside the global leaders in metal additive

No one knows your business like you do. No one knows metal additive like we do. Together, we can transform the way business is done.

Transformative technology—Electron Beam Melting

EBM's unique stacking capability takes advantage of the maximized build envelope. With EBM, parts can be nested and stacked on top of one another without having to be connected to the build plate or the parts below. Discover how EBM can be your true competitive advantage.

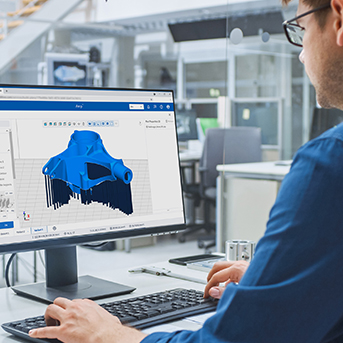

AMP WHITE PAPER

Get to industrialization faster

GE Additive now brings together all additive manufacturing build-prep tools into one powerful software platform called Amp.

ROI PLAYBOOK

ROI starts with a business plan

Create a comprehensive business case and move to production – faster – with the four steps outlined in the playbook Building the Business Case: Identifying Criteria to Measure ROI for Additive Manufacturing.

Join the team

We see a brighter future for the world and your career. The world is a place of increasingly complex challenges and it’s looking to us to solve them. Do you have the vision and the ambition for this kind of challenge?