Composites

Composites are materials made from two or more constituent materials that leverage attributes from each of the constituents. The most common class of composites are fiber reinforced structural composites. GE Research has deep experience in the development, characterization, and production scale-up of both fiber reinforced Ceramic Matrix Composites (CMCs) and Polymer Matrix Composites (PMCs). CMCs utilize ceramic fibers, with a special interface coating, inside of a ceramic matrix. This combination of materials provides ceramic like temperature capability (1500°F-3000°F) with metal like durability and significant weight savings compared to metals. PMCs utilize glass, polymer, or carbon fibers inside of a polymer matrix which combines the strength and stiffness of the fibers with the load transfer capability of the matrix. GE Research has teams dedicated to composite processing, process modeling, mechanical and environmental testing, microstructure-property modeling, and composite lifing. GE Research's experience includes producing and understanding each composite constituent including reinforcing fibers, fiber coatings, matrices, and environmental barrier coatings (EBCs). The capability to understand and develop these composites and their constituents provides a distinct advantage in the commercialization and monetization of these technologies. For example, GE Research developed a melt infiltrated CMC system, and its EBC, that GE Aviation has commercialized and is used in the CFM Leap and GE9X commercial jet engines. GE continues to innovate in this space with the development of new composite systems for military and commercial applications.

Polymeric Materials

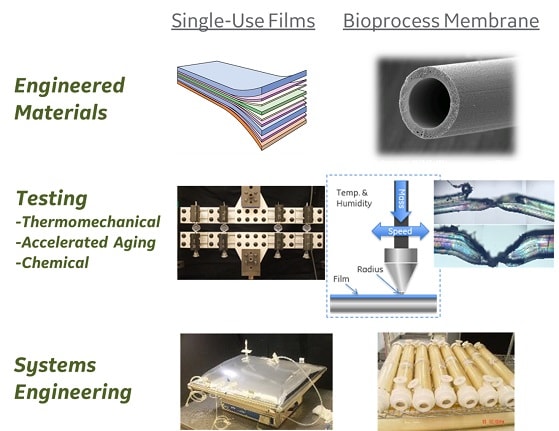

GE Research's polymer expertise builds on a rich legacy of material development for all of our GE businesses, including Aviation, Healthcare, Power and BHGE, and our former GE Plastics, Silicones and Advanced Materials businesses. Core competencies include advanced materials design and fabrication, structure-property-performance evaluation, monomer and polymerization process development, characterization, physical property testing, and polymer processing and scale-up. Some recent research areas where polymeric materials have been key system enablers include:

- Innovative biopharmaceutical processing products: 1) low-fouling, instantly wettable hollow fiber membrane for the purification of biological drugs. The hardware and filtration systems are based on an novel, hydrophilic polymeric material that is leading to improved productivity for challenging biological feeds. 2) single-use disposable bags for upstream bioprocessing based on engineered, multi-layer plastic films (Fortem™)

- Biospecimen Stabilization: lignocellulosic-based matrices impregnated with unique chemistries to enable dry storage of DNA, RNA and proteins under ambient conditions

- Valves: advanced blowout preventers and stem seals for oil & gas applications

- Thermoplastics & Thermosets: 1) enabling, modular wind blades for Renewable Energy generation 2) icephobic thermosets for propellers and blades