With GE Vernova standing at the threshold of becoming a new purpose-built, energy-focused company in a few short weeks, it’s worth noting the inspiration for its name. It is, says the company, “a combination of ver, derived from verde and verdant to signal the greens and blues of the Earth, and nova, from the Latin novus, or ‘new.’” Novus also happens to be one of the roots of the word “innovation,” a pillar of GE from its founding. Innovation, then, is literally in the company’s DNA.

“The other thing that I think would really surprise folks to know is that within the next 10 years we’re going to have about 3.5 million jobs in manufacturing that are available,” Timmons said.

#GEGarages event kickstarted on the 18th of August in Ciputra Artpreneur, Jakarta, Indonesia.

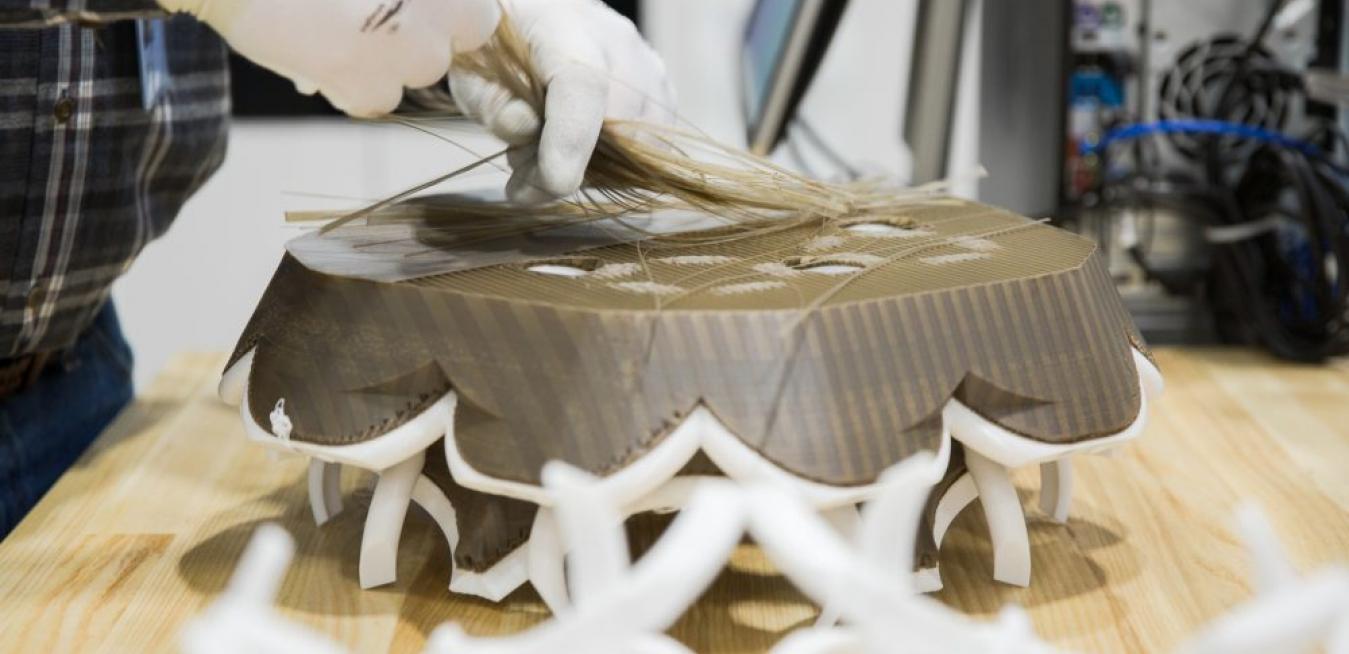

After 20 years of iteration on the same basic additive-manufacturing technologies for metal, a new wave of innovation is emerging. Lower-cost, safer processes are replacing the old ways of doing things, offering vastly different material properties through resolution, surface quality and design freedom.

Manufacturing is a hot topic again, undergoing the industry’s greatest change in more than 100 years. Domestic jobs have evaporated from many countries with globalization, offshoring may be reverting to near shoring and automation threatens to replace more workers every day. The way we build and deliver the goods and products that fuel our economies and our lives will never be the same.

Making spare parts doesn’t sound like ground zero for a technological revolution. But at a time when the entire manufacturing workforce is bracing itself for the changes sweeping the industry, the concept of “replacements” takes on extra resonance.

From hearing aids to jet engines, 3D printing is revolutionizing the world of manufacturing. How will commerce change when thousands of products, from cell phones to blenders, are customizable? Even though 3D printing is a 30-year-old technology, we’re just scratching the surface of where additive manufacturing will take us, writes Alan Amling, vice president of corporate strategy for UPS.

Of all the ways 3D printing will change the world, the democratization of manufacturing is perhaps the most important.